There are certainly many brands in the world of photography that are well known. And among those brands, there are plenty of customers who are very passionate, or act as defacto “brand ambassadors” for them. You’re probably thinking of your favorite as you read this. But the one thing that all can agree on, is that in the photographic community, the name “Leica” is synonymous with precision, luxury, and quality.

I (pictureline employee, Nick Gilson) recently had the opportunity to participate with professionals from Austria, Italy, Sweden, and the U.S., in a program called “Welcome to Leica,” which is hosted eight times a year at Leica’s headquarters in Wetzlar, Germany. Being an unofficial brand ambassador myself, I was thrilled to go. But even my high expectations were exceeded over my week in Germany.

The Leica Headquarters – The building on the right is designed to look like a lens while the left is designed to reference binoculars and the sport optics division.

The Leica Headquarters – The building on the right is designed to look like a lens while the left is designed to reference binoculars and the sport optics division.

The Ernst Leitz Optische Werke was a moderately successful optics company, specializing in microscopes in the early 20th century. Enter engineer Oscar Barnack, who, being a photography enthusiast who suffered from asthma, received approval from company president Ernst Leitz to spend time developing a camera that would utilize movie films of the time, but that would be significantly smaller and lighter weight than the medium and large format cameras then available to the public.

The result in 1914, the “Ur-Leica” (derived from combining the names Leitz-Camera), forever changed the world of photography by introducing the 24x36mm format that would eventually become the standard recognized by camera brands worldwide, and over 100 years later remains the basis for digital imaging systems.

The “Ur-Leica” - this prototype would eventually become the Leica I which started selling in 1924.

The “Ur-Leica” - this prototype would eventually become the Leica I which started selling in 1924.

This is a reproduction of the original, which remains in an undisclosed location due to its extreme historical significance.

This is a reproduction of the original, which remains in an undisclosed location due to its extreme historical significance.

Since the beginning of its focus on photographic products in 1924, Leica has prioritized quality above all else. But this emphasis on quality has been paired with creating a culture of family and supporting their staff through progressive policies and programs.

Ernst Leitz recognized in the first decade of the 20th century that tired and overworked employees could not produce the highest quality products and implemented an 8-hour workday years before it was the norm. His son and predecessor, Ernst Leitz II, provided several Jewish employees letters of recommendation, positions, and/or resources to escape Germany in the 1930s and during World War II. As recently as the 1990s, Leitz executives were known to provide housing assistance to long-time employees relocating to different areas of the world.

The Leica I, the world's first commercially produced 35mm camera.

The Leica I, the world's first commercially produced 35mm camera.

I arrived in Germany early on November 12, needing plenty of time to acclimate to the time change from my starting point in Salt Lake City, UT. My destination was the Ernst Leitz Hotel, officially the Vienna House, in the heart of the Leitz Park, which houses not only the hotel, but the Leica Store Wetzlar, the Ernst Leitz Museum, the Leica Archives, Leica Cine HQ, as well as their unique headquarter building and manufacturing facility.

Leica Welt, or “Leica World” on the outskirts of Wetzlar, Germany

Leica Welt, or “Leica World” on the outskirts of Wetzlar, Germany

Our first full day of training, led by the amazing Janina von Rueden, gave us all an overview of the history of Leica, both as a manufacturer and as a company committed to the well-being of its employees. Leica’s commitment to a focus on family was reinforced, as our group of trainees shared our first dinner at Olafs Kochschule, a German cooking school in the heart of Wetzlar.

Paired randomly alongside senior employees from Leica, and under the direction of Olaf himself, we crafted a gourmet meal that not only fed our bodies but served to bond us together as a group for the remainder of our week. Impressed upon all of us as well, was that the even highest level executives considered themselves part of this family, and prioritized being a part of welcoming us into it.

Our group, roaming the streets of Wetzlar after dinner.

Our group, roaming the streets of Wetzlar after dinner.

This building was famously photographed by Oscar Barnack with the Ur-Leica, and is accepted as the first image from a 35mm camera. Leica enthusiasts from all over the world reproduce this image daily.

The next day, we were thrilled to have a tour of the camera and optics manufacturing facility. There are literally no variables which are not considered in the manufacturing process, from an additional building hallway to serve as a thermal barrier, to locating critical optics machines as far away as possible from passing local traffic on a nearby street. We were guided by Optics Manufacturing Group Leader Roland Elbert, who showed us many technical aspects of the tooling process, processes of prototyping new models, and most interestingly, the incredibly laborious process of individually polishing every element that goes into a Leica lens.

Roland, having worked at Leica since the 1980’s, could look at any optical element and not only tell us what lens it came from, but where in the design it belonged. Product tolerances and calibrations exist at a level that many other manufacturers can not even measure, let alone match. Still, the focus on precision and quality remains the priority.

Several times, when we were on the tour, Roland reminded us that even though these processes take time, Leica refuses to speed up the process if a compromise in quality is even possible. Whether it is polishing optics, assembling lens housings, or engraving bodies, perfection remains the priority.

A few samples of the different parts required for the M-series lenses.

A few samples of the different parts required for the M-series lenses.

Samples of top plate engraving, either as part of a special edition release, or special request by customers wishing to customize their camera.

Samples of top plate engraving, either as part of a special edition release, or special request by customers wishing to customize their camera.

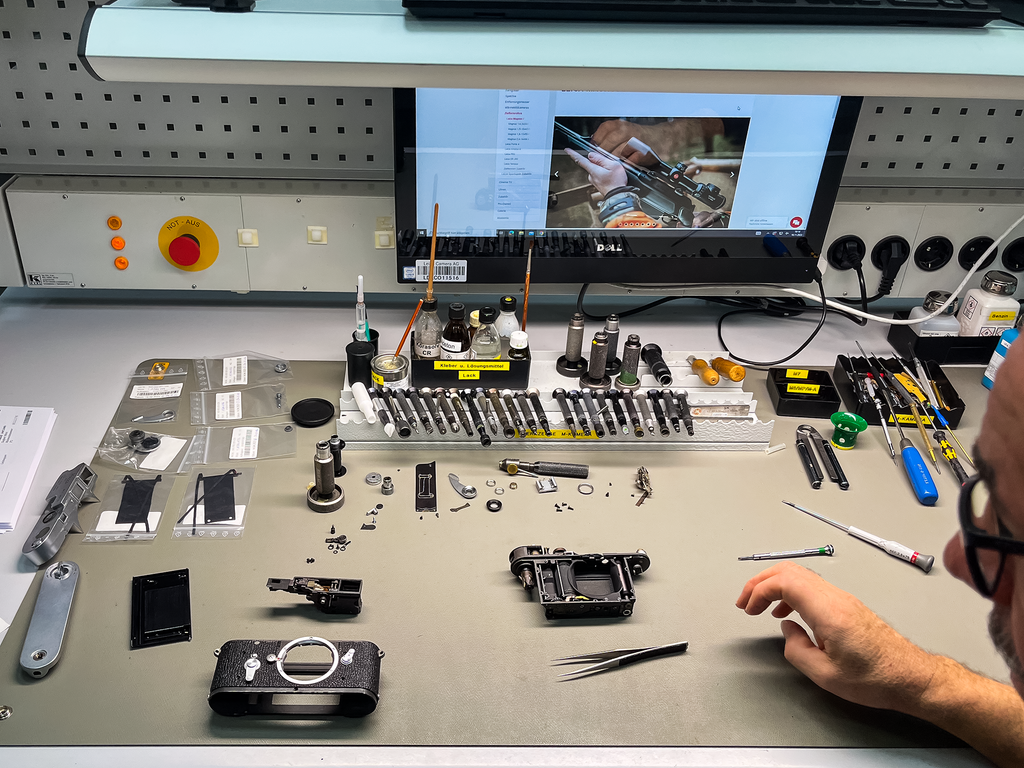

On Thursday, we were able to visit the customer care center, where cameras and lenses are sent for repair and maintenance. We were all amused to learn that one of the very first steps in the process occurs in receiving, where all items are analyzed for, and quarantined if fungus is detected. Special clothing is provided, and discharge stations are placed, to ensure that no electromagnetic damage can occur as part of the repair process.

One of the most interesting parts of this tour was when we were able to observe a senior repair technician completely disassemble an M3 body from 1956 to replace the winding mechanism and perform a CLA. As you would expect, just like the manufacturing process, commitment to quality is unfaltering, and no specification is overlooked. Compared to a modern M body, and aside from the electronic components, this M3 was nearly identical when broken down.

This M3, sent in for service, just minutes after service began.

This M3, sent in for service, just minutes after service began.

The shutter mechanism of the 1956 M3, on the left, is remarkably similar to the modern shutter assembly used today.

The shutter mechanism of the 1956 M3, on the left, is remarkably similar to the modern shutter assembly used today.

Now, nearly fully disassembled, replacing parts can begin.

Now, nearly fully disassembled, replacing parts can begin.

Also included on Thursday was a tour of the Leica Cine division, where we learned that the tolerances and expectations of the Leica Cine lenses are in an entirely different world, even for Leica. Being able to observe engineers assembling, cleaning, and testing these lenses which most of us will never have the privilege of using, was an incredible experience.

Last, but certainly not least, was a special (and not publicly available) tour of the Leica archives. Copies of historical publications, camera schematics personally approved by Oscar Barnack himself, were all incredibly interesting, but a group favorite was the camera archives. Nearly unused samples of the Leica I, sales samples from the 1920’s all over the world, stored with rare and unique models like the M4-2 Half Frame (only 10 were manufactured).

The M9P Hermes Edition

The M9P Hermes Edition

Despite running over on time, we were all thrilled to watch as archive director Tim Pullman was kind enough to search the handwritten records, still stored by Leica, to identify the manufacture year, delivery date, and dealer, for the Leica I owned by one of our group members.

The early delivery records, listing every camera serial number, are still kept in the Leica archives and referred to when customer inquiries are made.

The early delivery records, listing every camera serial number, are still kept in the Leica archives and referred to when customer inquiries are made.

As I shared at the beginning of the post, I headed into this experience already a fan of Leica products, and with high expectations. I can confidently say that after a week of seeing the level of precision and care that is put into each product, any hype or talking points you may have heard from your local dealer are, if anything, understated. And although frustrating, delays to get the latest 35mm APO-M, Q3, or whatever future product you’re looking for, know that it’s for good reason, and worth the wait.

If you’re in Germany and can spend a day or two in Wetzlar, I highly recommend a night in the Vienna House, with a visit to the Ernst Leitz museum and any factory tours that may be available at the headquarters. Just like owning a piece of Leica equipment, it will exceed your expectations.

1 comment

Janos

I was attended Leica’s annual meeting in October as a member of Leica Society International ((LSI). For anyone who loves the brand doing likewise is a no-brainer. Wetzlar is wonderful too. Go for it Leica fans; you won’t regret it.